1-800-805-5783

1-800-805-5783

The traditional supply chain landscape has been characterized by its complexity, vulnerability, and susceptibility to disruptions.

Technology has the potential to revolutionize AI in supply chain management by harnessing data-driven insights, predictive analytics, and automation, offering a beacon of hope for a more efficient and reliable AI in the future of supply chains.

The advent of artificial intelligence (AI) presents a promising solution to the challenges faced by the traditional supply chain landscape.

Factors such as global economic fluctuations, natural disasters, and geopolitical tensions have made it increasingly difficult for businesses to maintain efficient and reliable supply chains.

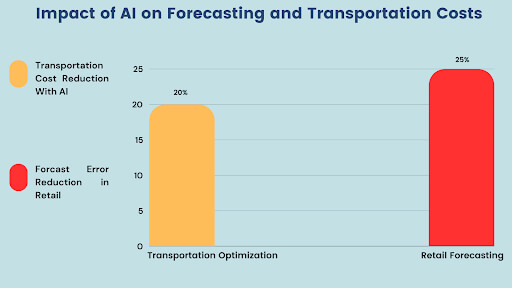

Artificial intelligence (AI) is also transforming the transportation and logistics industries. By analyzing real-time traffic data, weather conditions, and other crucial factors, AI can optimize routes, reduce transportation costs, and improve delivery times.

This not only decreases fuel consumption and travel time but also enhances customer satisfaction through timely deliveries.

AI’s ability to process vast volumes of data highlights its immense potential in strengthening supply chain resilience and agility. Its intelligent insights can improve risk management, transportation planning, inventory optimization, and demand forecasting.

Furthermore, AI can significantly enhance supply chain performance by automating repetitive tasks and processes, leading to substantial cost savings and increased operational efficiency.

Artificial intelligence has become a powerful tool for transforming supply chain operations.

By leveraging its capabilities, businesses can enhance efficiency, reduce costs, and improve decision-making.

At the core of AI are several key components:

AI can be applied to various features of AI in supply chain management, including:

Demand Forecasting:

Inventory Optimization:

Transportation Planning:

Risk Management:

Quality Control:

A significant update to the AI landscape is the rise of Generative AI (GenAI), which creates new content (e.g., text, data, simulations) based on its training data. GenAI brings new capabilities to the supply chain:

The COVID-19 pandemic exposed the vulnerabilities of global AI in supply chains. Disruptions caused by lockdowns, border closures, and supply shortages highlighted the urgent need for greater resilience.

It empowers proactive risk management, enhances visibility, and facilitates effective contingency planning, instilling confidence in businesses facing potential disruptions.

To identify potential risks, AI can explore vast amounts of data from various sources, including chronological trends, real-time market conditions, and geopolitical events.

Machine learning algorithms can catch patterns and anomalies that may indicate impending disruptions.

By proactively assessing risks, businesses can take preventive measures to mitigate their impact.

Predictive analytics, a subset of AI, uses historical data and statistical standards to forecast future events.

By analyzing past trends, AI can predict potential disruptions, such as natural disasters, labor shortages, or transportation bottlenecks, enabling businesses to develop contingency plans and allocate resources accordingly.

AI-powered supply chain visibility and traceability provide real-time information about the location and quality of products throughout the supply chain, enabling businesses to track shipments, identify bottlenecks, and respond promptly to disruptions.

Blockchain technology, often integrated with AI, can ensure the authenticity and integrity of data, enhancing transparency and trust.

AI has emerged as a potent tool to enhance supply chain agility, empowering businesses to respond to disruptions and evolving customer needs with speed and efficiency.

Optimizing Inventory Management

AI-powered inventory management systems can significantly reduce holding costs and improve stock levels.

AI algorithms can accurately predict demand and optimize inventory replenishment by analyzing historical data, demand patterns, and real-time information.

This helps avoid stockouts while minimizing excess inventory.

AI-driven demand forecasting utilizes advanced statistical models and machine learning techniques to deliver more precise predictions.

By considering economic indicators, seasonal trends, and customer behavior, AI can help businesses anticipate demand fluctuations and adjust their supply chains accordingly.

AI can revolutionize transportation and logistics operations. AI-powered route planning algorithms can optimize delivery routes, reducing travel time and fuel consumption.

Load optimization tools can ensure efficient utilization of transportation resources, minimizing costs and environmental impact.

Real-time tracking systems powered by AI provide visibility into the movement of goods, enabling proactive response to unexpected events.

AI can revolutionize supply chain management by optimizing processes, improving efficiency, and enhancing decision-making. However, its implementation is not without challenges.

Data Quality and Availability: The Fuel for AI

High-quality, trustworthy data is the lifeblood of AI applications. The AI in the supply chain encompasses data from various sources, including sensors, IoT devices, ERP systems, and transportation networks. Data accuracy, consistency, and completeness are crucial for AI models to deliver accurate insights and predictions.

Data availability can also be a Challenge:

Some AI in supply chain data may be siloed differently from departments or systems, making it hard to access and combine. Implementing data governance strategies and investing in data management tools can help address these issues.

Integration with Existing Systems: Bridging the Gap

Integrating AI solutions with living AI in supply chain systems can be a complex process. Technical challenges such as compatibility issues, data formats, and legacy systems may arise.

A phased approach can mitigate integration risks. Starting with more minor, less complex use cases and gradually expanding AI implementation can reduce disruption and ensure a smooth transition.

Ethical Considerations: Humanizing AI

AI has the potential to displace jobs in the supply chain. Automating inventory management and transportation planning tasks could lead to job losses.

It’s essential to consider the social and economic implications of AI adoption.

Strategies like retraining programs and job creation initiatives can help mitigate the adverse impacts and ensure a just transition.

Bias in AI algorithms is another ethical problem. If AI models are instructed on biased data, they may memorialize existing inequalities.

Ensuring fairness and transparency in AI development is crucial.

Cybersecurity: Protecting the Digital Supply Chain

Cybersecurity is a top priority for AI in the supply chain. As AI systems become increasingly interconnected, they are vulnerable to cyber threats such as data breaches, ransomware attacks, and disruptions in the supply chain.

Implementing robust cybersecurity measures is essential. This includes:

Addressing these challenges and references can help organizations harness the power of AI to optimize their supply chain operations, enhance efficiency, and gain a competitive advantage.

Looking ahead, AI continues to shape the next generation of supply chains by enabling organizations to make autonomous decisions, optimize logistics, and use resources sustainably.

Emerging trends include:

Organizations that embrace and implement AI-driven supply chain transformation today equip themselves to navigate tomorrow’s uncertainties with speed, efficiency, and confidence.

In conclusion, AI offers immense potential to transform supply chain and logistics management.

By leveraging its capabilities, businesses can improve efficiency, reduce costs, and enhance customer satisfaction.

As AI continues to develop, we can expect even more innovative applications.

AI offers immense potential to transform the AI supply chain by optimizing processes, improving efficiency, and enhancing decision-making.

However, realizing these benefits requires careful consideration of data quality, integration, ethical considerations, and cybersecurity challenges.

Addressing these issues can help organizations harness the power of AI to create more resilient, sustainable, and competitive supply chains.

AI can help businesses navigate disruptions and ensure a more trustworthy and efficient supply chain by enabling proactive risk management, predictive analytics, and improved visibility.

As the world becomes increasingly interconnected and volatile, adopting AI in supply chain management will be crucial for long-term success.

AI enhances supply chain resilience by predicting disruptions, optimizing inventory levels, and facilitating faster decision-making through real-time data analysis.

AI analyzes historical data and market trends, providing accurate demand predictions that help reduce overstocking and stockouts.

Initial costs may be high, but the long-term savings from efficiency, reduced disruptions, and better resource management typically outweigh the investment.

AI is used for predictive maintenance, demand forecasting, inventory management, and optimizing transportation routes.

AI identifies potential risks by analyzing data from various sources, enabling proactive measures to mitigate disruptions.

At [x]cube LABS, we craft intelligent AI agents that seamlessly integrate with your systems, enhancing efficiency and innovation:

Integrate our Agentic AI solutions to automate tasks, derive actionable insights, and deliver superior customer experiences effortlessly within your existing workflows.

For more information and to schedule a FREE demo, check out all our ready-to-deploy agents here.