1-800-805-5783

1-800-805-5783

Supply chains are the backbone of your business. If your supply chain breaks, customers wait longer; costs rise, and efficiency drops. In 2025, AI agents’ supply chains are driven by data more than by trucks or ships. You can’t keep up with global trade and unpredictable demand using manual systems. You need intelligence. That’s why companies are turning to AI agents in supply chain operations.

AI agents aren’t buzzwords. They are autonomous systems that monitor, make decisions, and take action. They work 24/7, adapt to new data, and solve problems before they disrupt your operations. A recent Gartner report (2025) indicates that 73% of top-performing retailers utilize autonomous AI systems to manage core supply chain functions. This isn’t theory; it’s happening now.

Let’s look at what AI agents in supply chains mean for you, how companies use them today, and the measurable benefits they deliver.

AI agents in the supply chain are intelligent software systems that use data, machine learning, and automation to act independently. In supply chain management, they:

Think of them as supply chain co-workers who don’t sleep, make fewer mistakes, and keep learning as conditions change.

Expert insight: “AI agents are not just tools. They are decision-makers that keep supply chains running even when humans can’t react fast enough.” – Dr. Elaine Porter, MIT Center for Transportation & Logistics.

AI agents in supply chains frequently face constant shocks, including raw material shortages, geopolitical tensions, rising fuel prices, and unexpected demand surges. You can’t afford that. AI agents give you resilience. They cut response times, lower risks, and create supply chains that adapt without waiting for human approvals.

The global supply chain is under stress. Fuel prices fluctuate, geopolitical conflicts disrupt shipping routes, and consumer expectations for fast delivery continue to rise.

The message is clear: AI agents aren’t just efficiency boosters, they’re survival tools.

AI agents in the supply chain process sales history, market signals, and external events to forecast demand with higher accuracy. They adjust inventory in real-time to prevent both stockouts and overstocking.

AI agents in the supply chain evaluate suppliers based on cost, reliability, and compliance. They rank vendors, flag potential risks, and recommend more favorable contracts.

AI agents in the supply chain manage delivery fleets, track shipments, and reroute goods instantly when problems occur.

Inside warehouses, AI agents in the supply chain coordinate robots, schedule staff, and balance workloads to optimize efficiency and productivity.

AI agents spot early warning signs of disruptions and trigger response plans before problems escalate.

Sustainability isn’t optional. Regulators and customers demand greener supply chains. AI agents help by optimizing transportation, reducing waste, and monitoring emissions.

When you use AI agents in supply chain operations, you gain measurable improvements. Let’s unpack the benefits more deeply:

AI agents automate manual processes, such as order tracking and approval workflows.

AI agents reduce excess inventory, optimize transport, and cut energy use.

When demand spikes, AI agents adjust stock allocation instantly.

AI agents integrate data across ERP, CRM, IoT, and logistics platforms, giving a live dashboard view.

AI agents reduce delivery delays, track orders in real-time, and minimize errors.

AI agents keep supply chains running when humans can’t react fast enough.

Expert insight: “Companies that adopt AI agents in their supply chain are 40% more likely to outperform peers on both cost and customer satisfaction.”

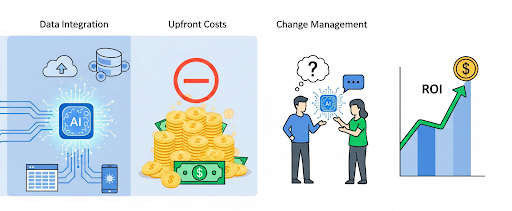

Adopting AI agents in the supply chain isn’t plug-and-play. You need to plan for:

But the ROI is clear. According to the 2024 report, companies that invested in supply chain AI saw an average ROI of 250% within three years.

Looking ahead, three significant trends dominate 2025 and beyond:

If you want to use AI agents effectively, follow this step-by-step roadmap:

AI agents in supply chain operations are not a future possibility; they are already a reality. They are today’s competitive advantage. From demand forecasting to risk management, these agents deliver faster decisions, lower costs, and greater resilience.

The question isn’t if you’ll adopt AI agents. It’s when. Start with one pilot, measure the results, and scale up. Companies that act now will not only survive the next disruption, but they will also thrive.

You don’t need to wait for the next disruption to act. Start piloting AI agents now. Your supply chain and your bottom line will thank you.

1. How do AI agents improve supply chain visibility?

They track real-time data across suppliers, warehouses, and logistics networks, giving you a single source of truth.

2. Can AI agents reduce costs in supply chain operations?

Yes. They lower transport expenses, optimize inventory, and cut manual labor costs.

4. What industries use AI agents in the supply chain?

Retail, manufacturing, logistics, healthcare, and consumer goods are leading adopters in 2025.

5. Are AI agents replacing human workers in the supply chain?

No. They complement humans by handling repetitive tasks, while people focus on strategy and exceptions.

6. How fast can I see results after adopting AI agents?

Most companies experience measurable improvements within 6–12 months, with the ROI compounding over time.

At [x]cube LABS, we craft intelligent AI agents that seamlessly integrate with your systems, enhancing efficiency and innovation:

Integrate our Agentic AI solutions to automate tasks, derive actionable insights, and deliver superior customer experiences effortlessly within your existing workflows.

For more information and to schedule a FREE demo, check out all our ready-to-deploy agents here.