1-800-805-5783

1-800-805-5783

Logistics in 2025 is fast, complex, and unforgiving.

Global freight costs rose by over 6% in the past year, and customer expectations for same-day or next-day delivery are at an all-time high. That means the old “ship and hope” approach no longer works. This is where AI in logistics changes the game.

You’re competing in an environment where speed, accuracy, and adaptability matter as much as price. Delivery delays damage customer trust instantly. Stockouts lead to lost sales. Extra storage and inventory tie up working capital.

Artificial intelligence helps you see problems before they cost money, optimize processes in real time, and react instantly to disruptions. Instead of chasing issues after they happen, you prevent them, saving time and cutting expenses.

The best part? You don’t need to replace your entire system overnight. AI works in modules. You can start with the areas that will make the most difference to your bottom line and then scale.

In this guide, you’ll see how AI in supply chain and logistics works, real-world examples, and the benefits of AI in logistics for both B2B and e-commerce.

The global logistics industry is growing fast, but so are its challenges. According to McKinsey’s 2025 supply chain report:

E-commerce is expanding, and logistics must handle higher volumes without sacrificing speed or profitability. AI makes that possible by replacing manual decisions with data-driven actions.

AI in supply chain and logistics isn’t just about replacing people with machines. It’s about giving your team better tools to make faster, more accurate decisions.

AI can process historical sales data, seasonal trends, supplier performance, and external factors like weather or economic shifts to predict demand with over 90% accuracy.

For example, a leading grocery chain used AI forecasting to reduce perishable waste by 17% in 2024. That’s not just about cost savings; it also results in less environmental impact.

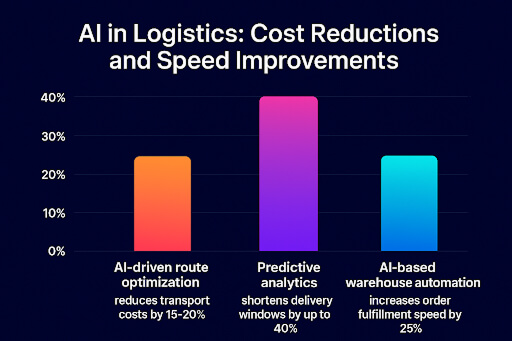

AI route planning takes into account live traffic data, road closures, weather patterns, and delivery windows to find the most efficient path. These optimizations can reduce fuel consumption by 10–15% and cut delivery times by hours each week.

AI doesn’t only power robots, it also manages how inventory is stored. Intelligent algorithms determine the optimal placement of each SKU in the warehouse to minimize walking distance and picking time.

In 2025, some fulfillment centers using AI-driven shelving and picking systems are processing 25–30% more orders without adding square footage.

The last mile is often the most expensive part of the journey. AI helps group deliveries intelligently, assign drivers dynamically, and track parcels in real time.

AI in logistics examples like these have reduced last-mile delivery costs by up to 20% in major cities.

When you apply AI to the right points in your supply chain, the cost reductions are measurable and repeatable.

These benefits of AI in logistics are not theoretical; real-world operations prove them.

Logistics speed isn’t just about moving trucks faster. It’s about shortening every link in the chain.

Real-Time Decision Making: AI processes live GPS, order, and traffic data instantly. If a highway accident blocks a route, AI reroutes trucks in seconds, avoiding delays without manual intervention.

Automated Sorting & Packing: AI-powered sortation systems can process up to 10,000 parcels per hour, several times faster than manual handling.

Adaptive Scheduling: When demand spikes during sales events, AI redistributes staff, inventory, and transport capacity automatically to keep turnaround times under 24 hours.

In a competitive e-commerce environment, reducing delivery time from three days to one can mean the difference between retaining and losing a customer.

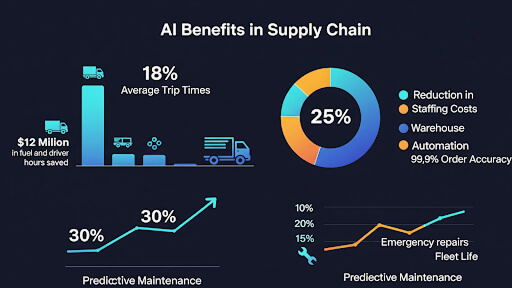

AI analyzes fuel use, labor allocation, and equipment performance. This ensures trucks follow the most efficient routes, warehouses use resources better, and maintenance happens before breakdowns.

Example: UPS uses AI-powered routing to save millions of gallons of fuel each year.

AI in logistics predicts traffic patterns, weather disruptions, and warehouse bottlenecks. This means shipments move without delays, even in complex global networks.

Example: DHL uses AI to reroute shipments in real-time when disruptions occur, reducing delivery times by hours.

AI-powered forecasting tools predict order spikes weeks in advance. This helps companies stock the right products in the right locations, reducing backorders and rush shipping costs.

AI in supply chain and logistics tracks stock levels in real-time and alerts teams before shortages happen. For e-commerce, this means no lost sales due to out-of-stock items.

AI chatbots provide instant shipment updates. Recommendation engines suggest faster delivery options during checkout, improving conversion rates and customer loyalty.

If you’re running an online store, you already know the race is for fast, cheap, and reliable delivery. Here are the benefits of AI in e-commerce logistics:

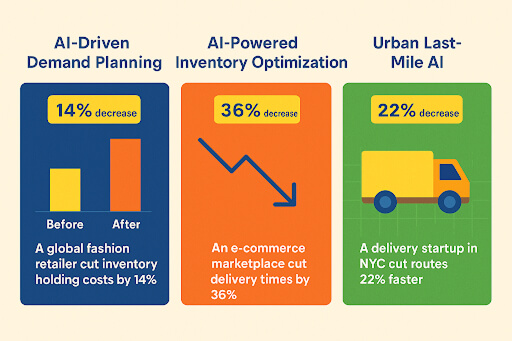

A global fashion retailer implemented AI demand planning in early 2024. By adjusting production and distribution based on AI forecasts, they cut inventory holding costs by 14% and avoided $9 million in markdown losses.

An e-commerce marketplace with multiple regional warehouses used AI to balance stock automatically. Products were moved closer to where they were likely to sell, which cut delivery times to rural areas by 36% and increased repeat purchase rates.

A delivery startup in New York City used AI grouping to batch orders headed to the same block, allowing drivers to finish routes 22% faster and make more drops per shift.

If you’re wondering what the benefits of AI in e-commerce logistics are, these examples give a clear answer: lower costs, faster delivery, and higher customer retention.

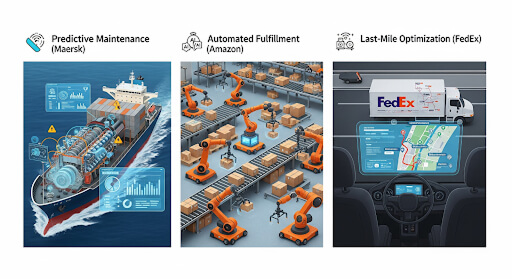

Maersk uses AI to monitor engine sensors on ships, predicting failures before they happen. This avoids costly downtime.

Amazon’s fulfillment centers use AI-guided robots to pick and pack orders, reducing human error and speeding up processing.

FedEx uses AI in logistics to plan delivery routes down to the minute, cutting fuel costs and delivery times.

“AI is transforming logistics from reactive to proactive. It allows companies to anticipate challenges before they impact deliveries.”

— Dr. Karen Li, Supply Chain Technology Analyst

If you want to start using AI in logistics without overhauling your operations, focus on these steps:

1. Assess Your Operations: Identify your most significant cost drivers or slowest processes.

2. Select Pilot Projects: Begin small, perhaps one warehouse or one delivery route to limit risk.

3. Measure ROI: Track savings in cost, time, and error reduction over a fixed period.

4. Refine the Model: Use your pilot data to fine-tune AI settings and workflows.

5. Scale Up: Once you prove value, expand AI to other routes, warehouses, or processes.

This structured approach keeps adoption controlled while ensuring each stage pays for itself.

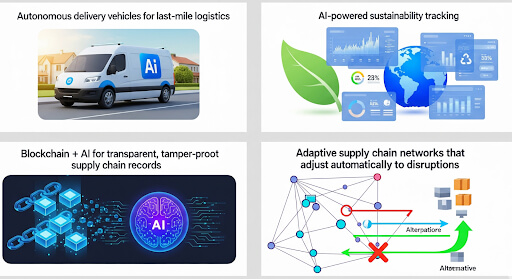

By late 2025, analysts expect AI in logistics adoption to reach new highs.

Gartner predicts that 40% of logistics firms will use AI for route optimization, and 32% will deploy AI for predictive inventory management. Autonomous trucks, AI-driven sustainability tracking, and real-time customs clearance are no longer experimental; they’re in pilot or early rollout phases.

Companies that act now will have a significant competitive advantage. They’ll cut operational waste, deliver faster, and make smarter decisions, all while meeting growing customer expectations for transparency and speed.

AI in supply chain and logistics isn’t just about keeping up; it’s about setting the pace.

1. What is AI in logistics?

AI in logistics uses algorithms, data, and automation to optimize routes, forecasting, warehousing, and deliveries.

2. What are the main benefits of AI in logistics?

It reduces costs, speeds up deliveries, improves demand forecasting, and enhances customer satisfaction.

3. How does AI help e-commerce logistics?

AI enables faster delivery, better inventory management, personalized shipping estimates, and fraud detection.

4. Can small businesses adopt AI in logistics?

Yes, AI works in modular solutions, allowing businesses to start small and scale gradually.

At [x]cube LABS, we craft intelligent AI agents that seamlessly integrate with your systems, enhancing efficiency and innovation:

Integrate our Agentic AI solutions to automate tasks, derive actionable insights, and deliver superior customer experiences effortlessly within your existing workflows.

For more information and to schedule a FREE demo, check out all our ready-to-deploy agents here.