1-800-805-5783

1-800-805-5783

The manufacturing industry stands at a transformational crossroads, where traditional production methods are rapidly giving way to intelligent, autonomous systems powered by AI Agents in Manufacturing. As we advance into 2025, these sophisticated digital entities are revolutionizing how factories operate, making decisions, and optimizing production processes with unprecedented precision and efficiency.

Unlike conventional automation systems that follow rigid, pre-programmed instructions, AI Agents in Manufacturing represent a quantum leap forward in industrial intelligence. These autonomous software systems can perceive their environment, analyze complex data patterns, make informed decisions, and execute actions independently, adapting to changing conditions in real-time without constant human oversight.

The journey from basic factory automation to today’s sophisticated AI Agents in Manufacturing has been remarkable. Traditional manufacturing relied heavily on mechanized processes designed for repetitive tasks with minimal variability. While effective for standardized production, these systems lacked the flexibility to adapt to new challenges or optimize performance based on emerging patterns.

Today’s AI agents for manufacturing go far beyond simple automation. They leverage advanced machine learning algorithms, neural networks, and real-time data analytics to create truly intelligent systems that can learn from experience and continuously improve their performance. These systems represent the backbone of Industry 4.0, where interconnected technologies create smart factories capable of autonomous operation and optimization.

The transformation is particularly evident in how these systems handle decision-making. Where traditional automation required extensive programming for every possible scenario, AI Agents in Manufacturing can evaluate new situations, learn from outcomes, and develop optimal responses autonomously. This capability makes them invaluable for managing the complex, dynamic environments that characterize modern manufacturing facilities.

AI Agents in Manufacturing are not science fiction; they are already being deployed on factory floors to tackle complex operational challenges. In predictive maintenance, these systems continuously monitor machine performance and sensor data to predict equipment failures before they happen. By scheduling maintenance only when needed, manufacturers can reduce unplanned downtime by up to 40% and maintenance costs by 20-25%.

Quality control represents another transformative application. AI agents in process manufacturing employ computer vision systems to inspect 100% of products as they move through production lines, identifying defects with accuracy rates often exceeding 99%. These systems can detect subtle visual anomalies, dimensional variations, or surface imperfections that might be missed by human inspectors, particularly during high-speed production runs.

In production optimization, AI Agents in Manufacturing serve as intelligent schedulers and supply chain planners, dynamically adjusting work sequences when conditions change and managing inventory by forecasting demand and triggering just-in-time replenishments. This coordination helps avoid both shop floor bottlenecks and material shortages while optimizing overall operational efficiency.

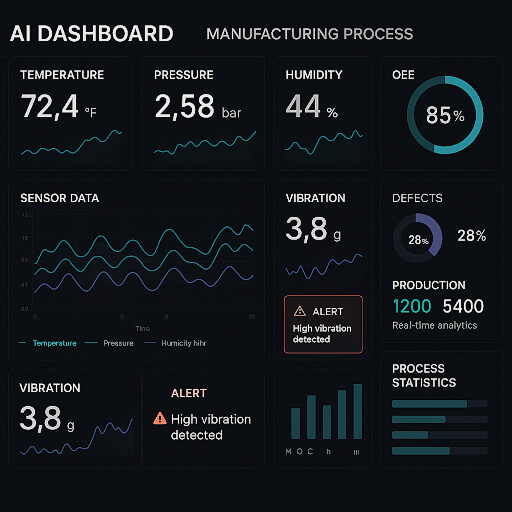

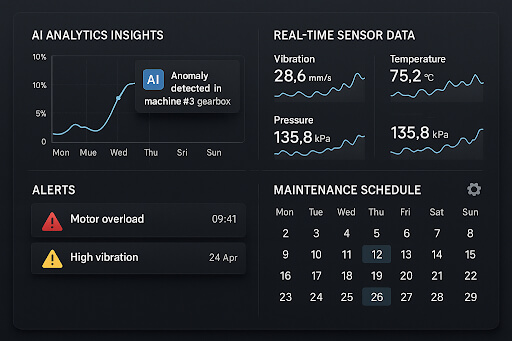

Innovative factory dashboard displaying real-time manufacturing process monitoring and quality control

The convergence of edge computing and artificial intelligence is enabling a new era of intelligent, autonomous systems directly on the manufacturing floor. Edge AI in industrial automation allows AI models to run directly on embedded systems and IoT devices, eliminating the need to send data to distant cloud servers for processing. This approach drastically reduces latency, boosts data security, and ensures uninterrupted operations even in environments with limited connectivity.

AI Agents in Manufacturing deployed at the edge can make split-second decisions locally, automatically adjusting processes to prevent faults and optimize performance in real-time. The global Edge AI in industrial automation market is expected to reach $268.5 billion by 2031, growing at an impressive 25.4% CAGR, driven by rising demands for real-time processing and operational agility.

Digital twins represent virtual replicas of physical assets that provide AI agents in manufacturing in 2025 with real-time operational context and understanding. These sophisticated simulations enable manufacturers to test and optimize changes in a risk-free virtual environment before implementation, running countless simulated scenarios to discover optimal solutions without disrupting actual production.

Traditional quality control processes often relied on sample-based inspections that could miss defects or identify problems only after significant production runs. AI Agents in Manufacturing have revolutionized this approach through continuous, comprehensive quality monitoring using computer vision and advanced sensor technologies.

Beyond simple defect detection, AI agents in process manufacturing provide valuable insights into the root causes of quality issues. By analyzing correlations between process parameters and quality outcomes, these systems can identify the specific conditions that lead to defects and recommend process adjustments to prevent future occurrences. This analytical capability transforms quality control from a reactive to a proactive discipline.

In process manufacturing environments, these systems continuously tweak parameters such as temperature, pressure, or ingredient mix based on real-time feedback. For example, an AI agent controlling a chemical reactor can modulate heating and stirring to ensure each batch stays within quality specifications, improving consistency and reducing waste.

Rather than replacing human workers, AI Agents in Manufacturing are creating new opportunities for collaborative intelligence in Industry 5.0. This paradigm recognizes that while AI excels at processing vast amounts of data and identifying patterns, humans bring irreplaceable skills, including creative problem-solving, contextual understanding, and strategic thinking. The Industry 5.0 market is projected to grow from $65.8 billion in 2024 to $255.7 billion by 2029, representing a 31.2% compound annual growth rate.

The collaborative approach proves particularly valuable in maintenance operations, where AI Agents in Manufacturing can diagnose potential equipment issues and recommend specific maintenance actions. At the same time, skilled technicians perform the actual repairs and provide feedback that helps the AI systems improve their diagnostic accuracy over time—companies implementing AI-human collaboration report 3.7x ROI on investments, with top performers achieving 10.3x returns.

Modern manufacturing intelligence solutions exemplify this collaboration perfectly, where AI processes real-time manufacturing data from sensors and systems, generates predictive insights about quality outcomes, and presents actionable recommendations to human operators. Humans remain in control, utilizing AI-generated insights to make informed decisions about process adjustments, maintenance scheduling, and quality interventions.

The implementation of AI Agents in Manufacturing delivers measurable returns across multiple performance dimensions. Manufacturers typically report productivity improvements of 10-30%, with some early adopters achieving even higher gains. These improvements result from optimized production schedules, reduced downtime, improved quality, and more efficient resource utilization.

Cost reduction represents another significant benefit, with manufacturers reporting operational cost savings of 15-25% through AI-driven optimization. These savings come from reduced maintenance costs, lower energy consumption, decreased waste, and improved inventory management. Quality improvements provide both cost savings and competitive advantages, with manufacturers implementing AI agents in manufacturing typically reporting a 30-50% reduction in defect rates by 2025.

Energy management represents a critical application where AI Agents in Manufacturing can analyze consumption patterns across different production scenarios and automatically adjust operations to minimize energy usage without compromising production targets. Some manufacturers report energy savings of 15-20% through AI-driven optimization of their production processes.

While the benefits of AI Agents in Manufacturing are substantial, successful implementation requires careful planning and attention to several key challenges. Data quality and integration represent fundamental requirements, as these systems depend on comprehensive, accurate data to function effectively. Manufacturers must invest in data infrastructure and develop processes for ensuring data quality across all operational areas.

Change management proves equally essential, as the introduction of AI agents in the manufacturing industry often requires significant adjustments to existing processes and workflows. Successful implementations typically involve comprehensive training programs, clear communication about the benefits and changes associated with AI adoption, and gradual rollout strategies that allow organizations to adapt to new ways of working.

Security and cybersecurity considerations become increasingly critical as AI Agents in Manufacturing become more integrated with operational systems. Manufacturers must implement robust security measures to protect against cyber threats while ensuring that AI systems can access the data they need to function effectively.

Looking ahead, AI agents in manufacturing in 2025 will become even more sophisticated, incorporating advances in edge computing, 5G connectivity, and quantum computing. These technological developments will enable even faster processing, more complex optimization algorithms, and enhanced real-time decision-making capabilities.

By 2025, experts predict that AI-driven automation and decision-making will become a standard part of manufacturing operations, not just in isolated pilots but across entire enterprises. This next wave will likely bring fully autonomous factories where AI agents run production with minimal human oversight, managing end-to-end operations from scheduling and maintenance to quality control and logistics.

Sustainability will play an increasingly important role in AI agents for manufacturing as companies seek to reduce their environmental impact while maintaining competitiveness. Future AI systems will incorporate environmental considerations into their optimization algorithms, helping manufacturers achieve their sustainability goals while optimizing operational performance.

The transformation of manufacturing through AI Agents in Manufacturing represents more than just a technological upgrade; it signifies a fundamental shift toward intelligent, autonomous production systems that can adapt, learn, and optimize continuously. As these systems become more sophisticated and widely adopted, they will define the competitive landscape for manufacturing companies worldwide.

Organizations that embrace AI Agents in Manufacturing today position themselves to benefit from improved efficiency, reduced costs, enhanced quality, and greater operational flexibility. The key to success lies in taking a strategic approach to implementation, focusing on data quality, change management, and workforce development while maintaining a clear vision of the transformative potential these technologies offer.

For manufacturing executives, plant managers, and digital transformation leaders, AI agents in the manufacturing industry are not just a buzzword but a practical tool for competitive advantage. The question is not whether to adopt these technologies, but how quickly organizations can implement them to maintain their competitive advantage in an increasingly intelligent manufacturing landscape. Embracing this technology now will position organizations for a more agile, efficient, and innovative future.

AI agents learn from data and adapt in real time; traditional systems follow fixed rules.

Typically, within 6–12 months, with 10–30% productivity gains and 15–25% cost cuts.

No AI handles data tasks, while humans focus on strategy and problem-solving.

Reliable sensor/ERP data, edge-compute hardware, secure networks, and standard protocols.

Begin with a small pilot (e.g., maintenance or inspection), measure results, then scale.

At [x]cube LABS, we craft intelligent AI agents that seamlessly integrate with your systems, enhancing efficiency and innovation:

Integrate our Agentic AI solutions to automate tasks, derive actionable insights, and deliver superior customer experiences effortlessly within your existing workflows.

For more information and to schedule a FREE demo, check out all our ready-to-deploy agents here.